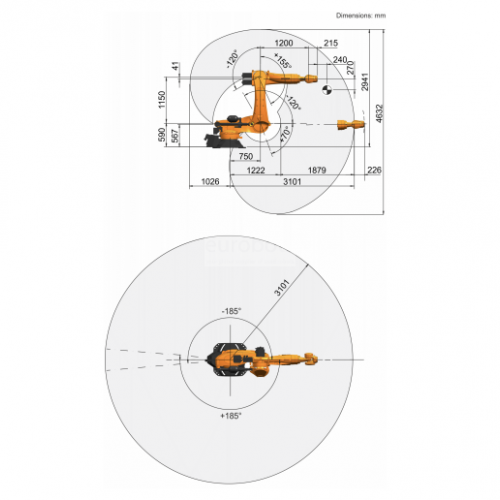

KUKA KR180 R3100 K PRIME

Industrial robot KR180 R3100K Shelf six axes. It's fast and precise robot with a payload capacity of 180 mm and arm range of 3,100 mm, it has a repetition accuracy of less than ± 0,06 mm. Suitable for general handling, arc welding and machining operations that require short time cycles.

KR C4 - Newest Kuka controller

More powerful, safer, more flexible, and above all more intelligent. The revolutionary concept of the KR C4 provides a firm foundation for the automation of tomorrow. It reduces costs in automation for integration, maintenance and servicing. The long-term efficiency and flexibility of the systems are increased at the same time. For this reason, KUKA has developed a new ground-breaking, clearly-structured system architecture that concentrates on open and powerful data standards. In this architecture, all integrated controllers – from SafetyControl, RobotControl, and MotionControl to LogicControl and ProcessControl – have a joint database and infrastructure which they use and share intelligently.

KR C4 features

- Simple to plan, operate and maintain

- Continuation of service-proven PC-based control technologies

- Quick and easy operation thanks to continued use of familiar operator control concepts

- Expansion of the set of commands for more user-friendly path programming

- High compatibility with previous programs for the KR C2

- Safety, Robot, Logic, Motion and ProcessControl in a single control system

- Real-time communication between the dedicated control processes

- Central basic services for maximum data consistency

- Seamless integration of safety technology for entirely new fields of application

- Integrated software firewall for greater network security

- Innovative software functions for optimized energy efficiency

- Future-compatible technology platform without proprietary hardware

- Multi-core processor support for scalable performance

- Fast communication via Gigabit Ethernet

- Integrated memory cards for important system data

- Designed for 400 – 480 VAC

- New fan concept for optimized energy efficiency

- Maintenance-free cooling without filter mats

- Highest performance in the smallest possible space

- Maximum availability

Main specifications

- Maximum Load of Robot: 180 Kg

- Number of axis: 6

- Maximum horizontal reach: 3100 mm (shelf)

- Repeatability: ±0.05 mm

- Controller: KR C4

Range of motion

- Axis 1: +/- 185º

- Axis 2: +70º/-120º

- Axis 3: +155º/-120º

- Axis 4: +/-350º

- Axis 5: +/-125º

- Axis 6: +/-350º

Robot Applications

- Assembly

- Pick and place

- Material handling

- Packing

- Arc welding

- Machining of soft materials

- Coating and glueing

Applications

Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts , Measurement , Assembly of parts , Laser cutting , Laser welding Nd-Yag , Glueing - Adhesive bonding , Stud welding , Plasma cutting , Advanced Manufacturing , Education

Pictures

Videos

Diagrams

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa