ABB IRB 6600

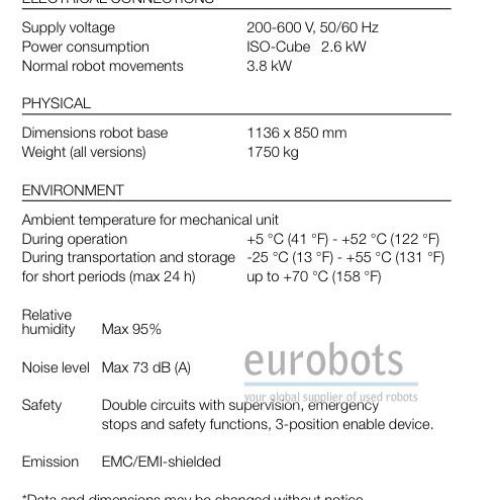

Year 2004. High payload robot available in five versions with a handling capacity of up to 225 kg, reach up to 3200 mm, and a wrist torque up to 1320 Nm. Evolution of the famous IRB6400. Higher speed and a fully new shape allowing a wider working envelope in axis 2 and 3. Single spring counterbalance system following the Kuka and Fanuc philosophy (Kuka series 2000 and Fanuc R2000). The IRB 6600 comes with a built-in Service Information System, allowing for it to easier plan service and maintenance.

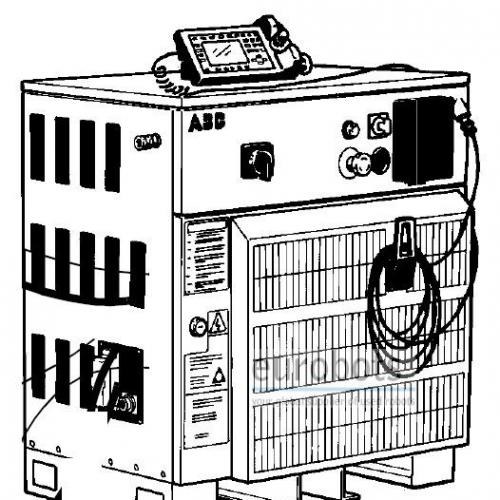

Equipped with the M2000 S4CPlus powerful controller.

S4Cplus gives you superior motion control. It features dynamic model based control, QuickMove for short cycle times, and the TrueMove function for high precision path following ability independent of robot speed. The S4Cplus system configuration capability and the powerful programming language RAPID make it easy to set up the controller for a wide range of applications. Two built-in Ethernet channels provide easier service and factory networking.

There are fieldbus and serial channels for PLC and PC connections.

The controller supports TCP/IP, DNS and other protocols. A dedicated robot protocol, RAP, is available for control and monitoring.

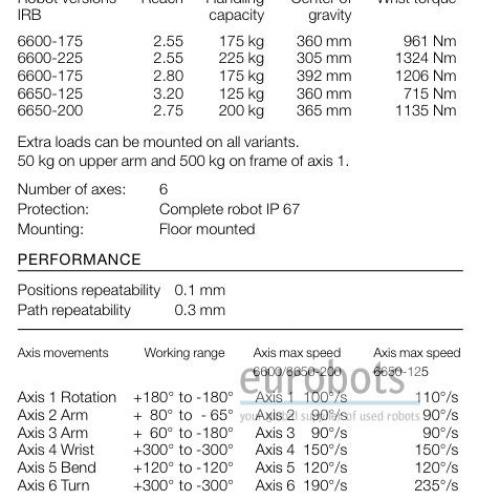

Robot Info

- Maximum Load of Robot: 155 Kg

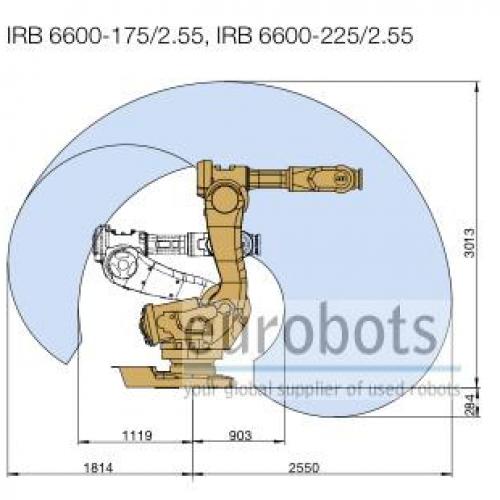

- Maximum Reach: 2550 mm

- Repeatability: 0.1 mm

- Controller: M2000 S4CPlus

Robot Motion Speed

- Axis 1: 100º/s

- Axis 2: 90º/s

- Axis 3: 90º/s

- Axis 4: 150º/s

- Axis 5: 120º/s

- Axis 6: 190º/s

Robot Applications

- Spot welding

- Press tending

- Material handling

- Machine tending

- Palletizing

- Assembly

アプリケーション

スポット溶接 , プレステンディング , パレタイズ , 部品のロードとアンロード , 機械加工 , 部品の取り扱い , 部品の組み立て , Laser cutting , Laser welding Nd-Yag , 接着-接着剤による接着 , Stud welding , プラズマ切断

写真

ビデオ

設計図

Spain

Spain

Germany

Germany

France

France

Russia

Russia

China

China

Argentina

Argentina

Portugal

Portugal

Colombia

Colombia

Italy

Italy

India

India

Brazil

Brazil

Japan

Japan

Mexico

Mexico

Turkey

Turkey

Ukraine

Ukraine

Peru

Peru

Sth. Africa

Sth. Africa