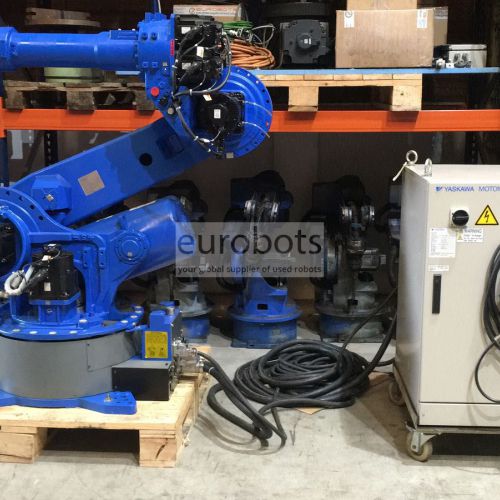

MS80W six-axis robot is a powerful and flexible robot, has 5 air lines for a variety of applications with a power saving system that reduces power consumption up to 25%, has a configuration where you can eliminate several stations, offering shorter production lines. Its high speed and acceleration reduces cycle times and increases production.

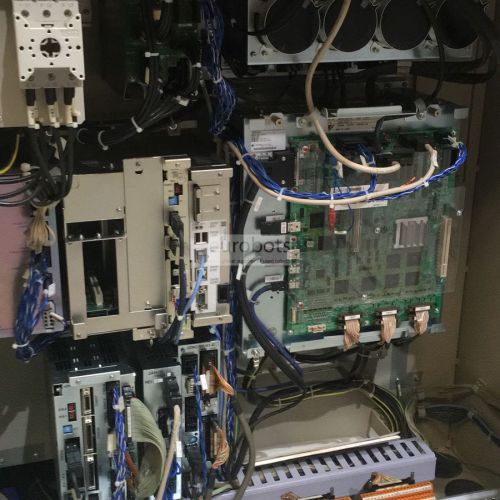

Characteristics of the DX100 controller

Yaskawa's compact DX100 controller with advanced structure and process control, offering greater freedom to the user even in the concept of an automated cell:

• Multirobot control system with up to 8 robots / 72 coordinated movement axes.

• Robust PC architecture, which provides system-level control for robotic work cells.

• Connections on the back of the control cabinet to optimize the interior space

• Built-in ladder logic processing; 4,096 I / O addresses

• Variety of fieldbus network connections

• High speed server connection

• I / F panels (10) show HMI on the pendant

• Advanced Robot Motion Control (ARM) for greater productivity and minimal learning time

• Energy saving up to 25%

• Repair time (MTTR)

• Easy maintenance with function to verify the status of the reducer, hardware diagnostic life function, improved problem resolution and alarm recovery

• Compact flash slot and USB port facilitate memory backups

• Small and lightweight Windows® CE programming pendant has a color touch screen with multi-window display capability.

Number of axis: 6

Maximum horizontal reach: 2,061 mm

Maximum vertical reach: 3,010 mm

Repeatability: ±0.07 mm

Controller: DX100

Axis L: +155°/-90°

Axis U: +160°/-185°

Axis R: ±360°

Axis B: ±125°

Axis T: ±360°

Axis L: 140°/s

Axis U: 160°/s

Axis R: 230°/s

Axis B: 230°/s

Axis T: 350°/s

Dispensing

Machine Tending

Press

Forming

Die Cast

Applications

Spotwelding , Press tending , Handling of parts , Laser welding Nd-Yag

Pictures

Videos

Diagrams