Years 2003-2004. KRC2 controller soft versions 4.1.4 or 5.2.17.

The KR 150/180/210 are masterful movers with a fist-shaped work envelope, and are ideal for the implementation of cost-effective, space-saving system concepts.

KUKA robots from the high payload range are particularly sought after for spot welding, handling and loading/unloading tasks. Their long reach and great flexibility make them indispensable partners.

Equipped with the modern KR C2 controller. The KR C2 robot controller makes programming easier with its Microsoft Windows interface. It is expandable, can be integrated into networks via a bus, and contains ready-made software packages.

KR C2 features:

- Open, network-capable PC technology

- 2 free slots for external axes

- DeviceNet and Ethernet slots for common bus systems (e.g. INTERBUS, PROFIBUS, DeviceNet) provided as standard

- Motion profile function for optimal interaction between the individual robot motors and their velocity

- Floppy disk and CD-ROM drives for data backup

- Facilities such as remote diagnosis via the Internet

- Simple operation and programming via KUKA Control Panel (KCP) with Windows user interface

- Compact control cabinet

- Ergonomic KUKA Control Panel (KCP)

Robot Info:

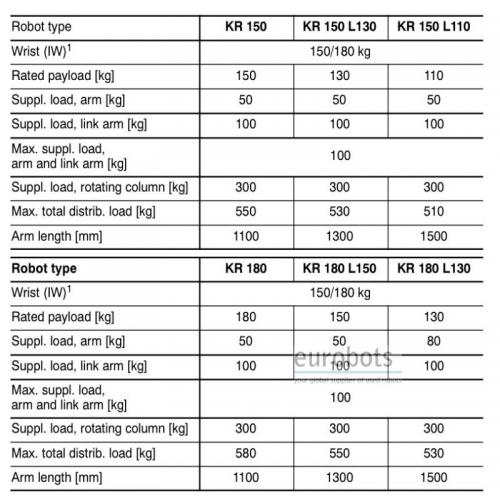

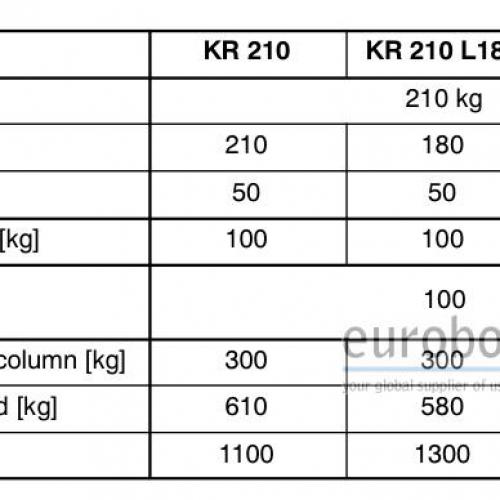

- Maximum Load of Robot: 150/180/210Kg.

- Maximum Reach: 2700/2900/3100 mm.

- Repeatability: 0.15-0.2 mm.

- Controller: KR C2 under Windows XP

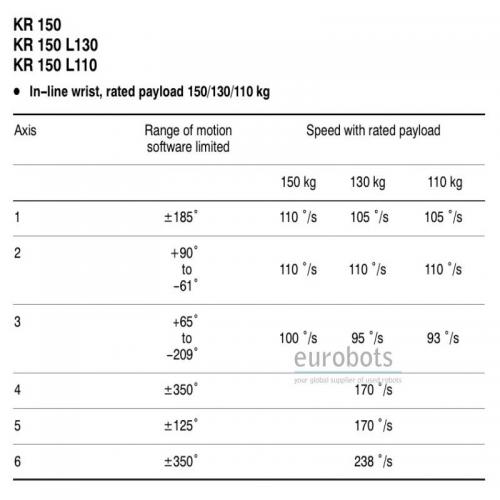

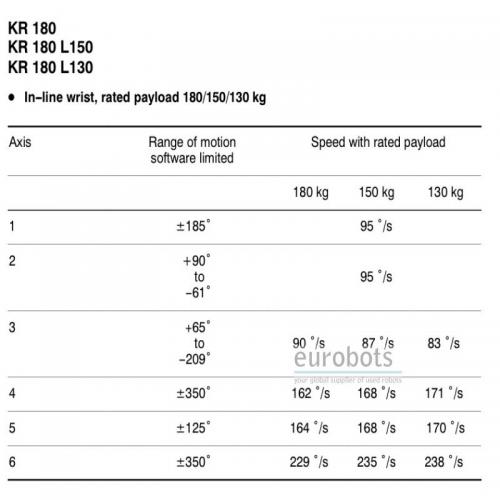

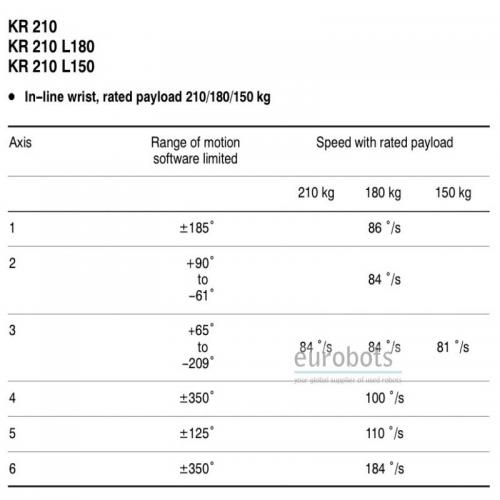

Robot Motion Speed:

- Axis 1: 105º/seg

- Axis 2: 110º/seg

- Axis 3: 95º/seg

- Axis 4: 170º/seg

- Axis 5: 170º/seg

- Axis 6: 238º/seg

Robot Applications:

- Machining

- Machine tending

- Polishing, grinding and deburring

- Coating and bonding

- Handling

- Measuring and testing

- Assembly

- Palletizing and order picking

- Cutting

- Welding

Applications

Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts

Pictures

Videos

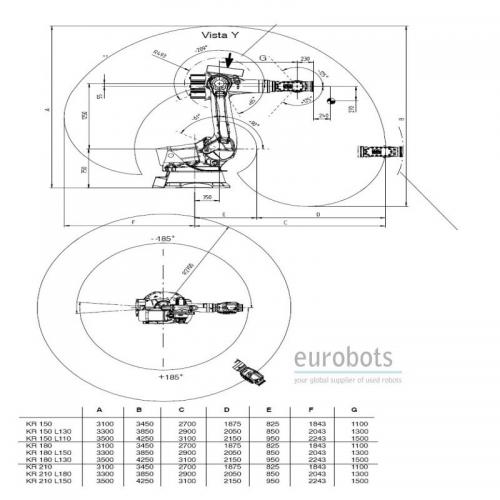

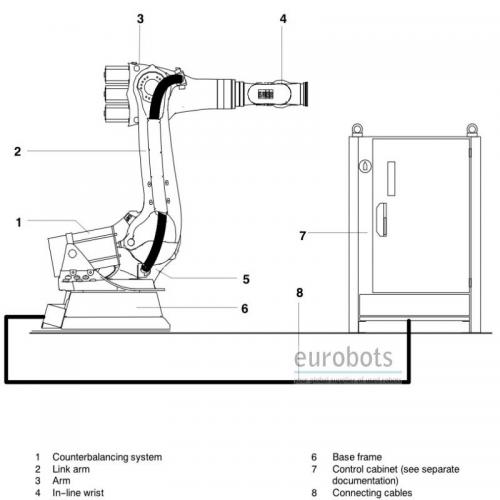

Diagrams