Heavy duty payload for applicactions which require heavy payloads.

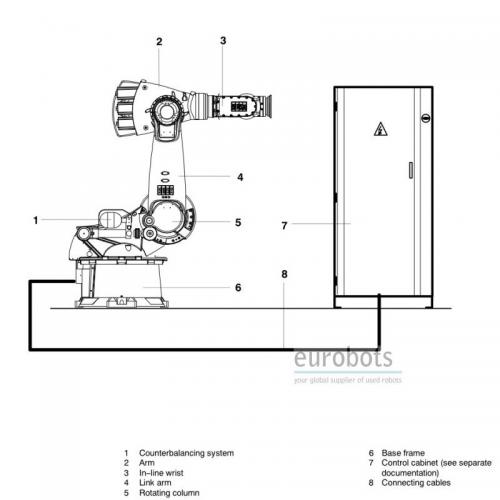

The robot KR 350 is a six--axis industrial robot for installation on the floor or on the ceiling. It is suitable for all point-to-point and continuous--path controlled tasks.

Equipped with the Windows 95 based KR C1A controller.

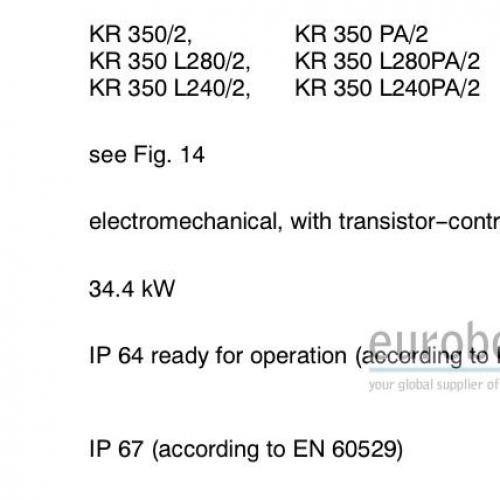

KR C1A controller specifications:

- Open PC technology with networking capability.

- CAN/DeviceNet and Ethernet as standard. Slots for common bus systems (e.g. INTERBUS-S,FIPIO).

- Integrated oscilloscope function for robot diagnosis and programming support.

- Motion profile function for optimum interaction between the individual robot motors and their velocity.

- Floppy disk and CD-ROM drives for backing up data.

- Facilities such as master/slave operation of robots or remote diagnosis via the Internet.

- Easy operator control and programming via KUKA Control Panel (KCP) with Windows 95

- graphic user interface.

- Compact, stackable control cabinet.

- One controller for all robot models.

- Ergonomic KCP design.

Robot Info:

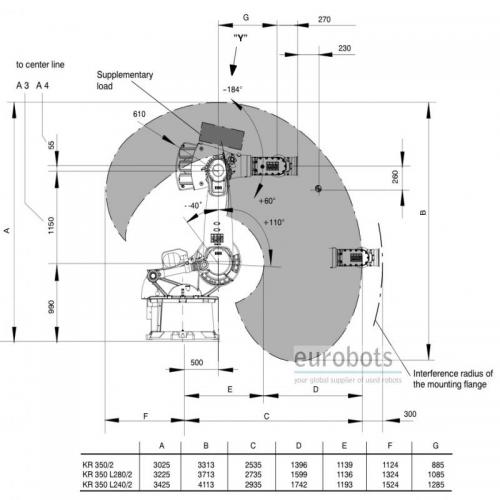

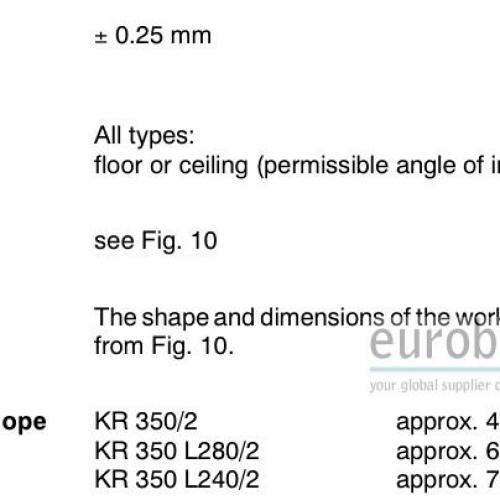

- Maximum Load of Robot: 350/280/240Kg.

- Maximum Reach: 2535/2735/2935 mm.

- Repeatability: 0,25 mm.

- Controller: KR C1A

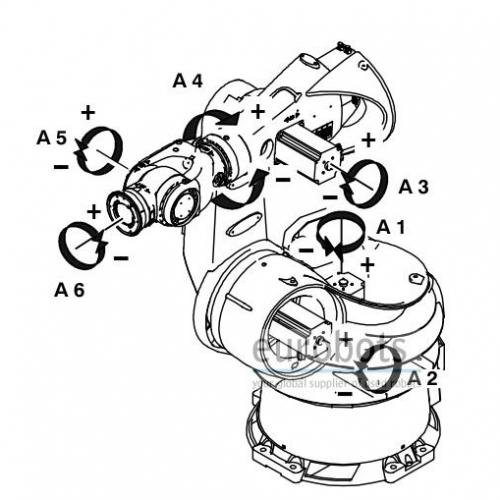

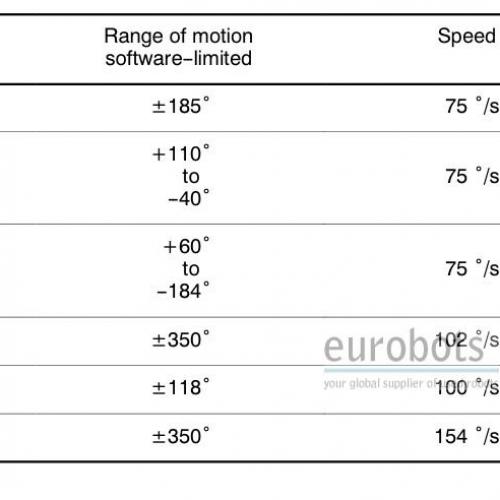

Robot Motion Speed:

- Axis 1: 75º/seg

- Axis 2: 75º/seg

- Axis 3: 75º/seg

- Axis 4: 102º/seg

- Axis 5: 100º/seg

- Axis 6: 154º/seg

Robot Applications:

- Handling, loading and unloading

- Packaging and order picking

- Spot welding and other welding processes

- Painting, surface treatment

- Metal casting machines, foundry plants

- Painting, enameling and other coating operations

- Application of adhesives and sealants

- Machining

- Waterjet cutting

- Machining

- Other machining operations

- Assembly

- Fastening

- Forging plants

- Cutting machine tools

- Measuring, testing and inspection

Applications

Spotwelding , Press tending , Loading and unloading of parts , Machining , Handling of parts , Laser welding Nd-Yag

Pictures

Videos

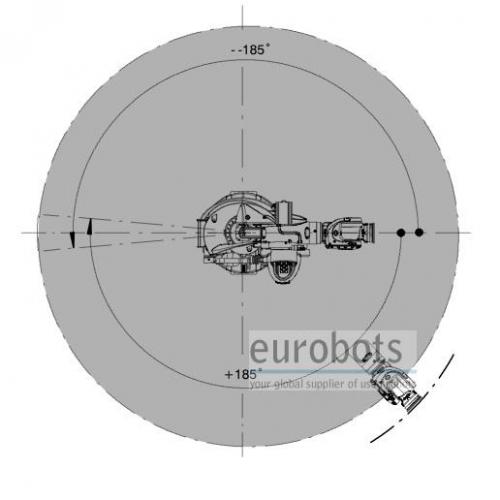

Diagrams