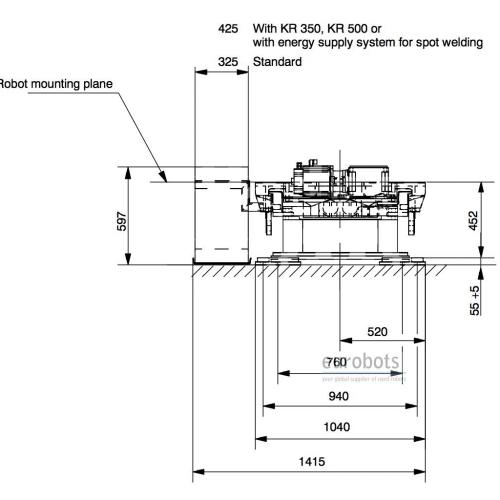

Kuka KR150-2 S2000 heavy payload industrial robot on a KL1500 7 axis linear track with lenghts ranging from 2000 to 15000 mm.

Available in three versions attending to the arm reach / payload: KR 150-2 (2700 mm / 150 kg) , KR 150L130-2 (2900 mm / 130 kg) , KR 150L110-2 (3100 mm / 110 kg).

Suitable for machining, spotwelding, measuring, handling and palletizing applications.

Equipped with the KRC2 controller available in two versions attending to the software version: 5.2.14 on WinXP with handling and welding software technologies.

The KR C2 robot controller makes programming easier with its Microsoft Windows interface. It is expandable, can be integrated into networks via a bus, and contains ready-made software packages.

KR C2 features

- Open, network-capable PC technology

- 2 free slots for external axes

- DeviceNet and Ethernet slots for common bus systems (e.g. INTERBUS, PROFIBUS, DeviceNet) provided as standard

- Motion profile function for optimal interaction between the individual robot motors and their velocity

- Floppy disk and CD-ROM drives for data backup

- Facilities such as remote diagnosis via the Internet

- Simple operation and programming via KUKA Control Panel (KCP) with Windows user interface

- Compact control cabinet

- Ergonomic KUKA Control Panel (KCP)

Robot basic data

- Maximum Load of Robot: 150/130/110 Kg

- Maximum Reach: 2700/2900/3100 mm

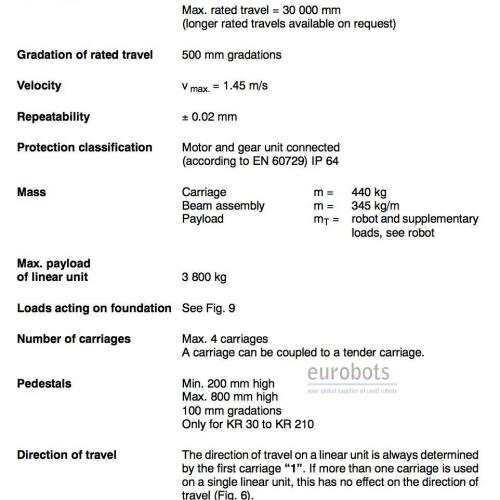

- Repeatability: 0.15 (0.02 mm for the 7 axis linear track)

- Controller: KR C2

Axis Speed in º/s for the models: KR 150-2 / KR 150 L130-2 / KR 150 L110-2

- Axis 1: 110º/s 105º/s 105º/s

- Axis 2: 110º/s 110º/s 110º/s

- Axis 3: 100º/s 95º/s 93º/s

- Axis 4: 170º/s (all 3 models)

- Axis 5: 170º/s (all 3 models)

- Axis 6: 238º/s (all 3 models)

- Axis 7: (speed in mm/s): 1450 mm/s

Range of motion (Axis 1 to 6)

- Axis 1: +- 185º

- Axis 2: +90 to -61º

- Axis 3: +65º to -209º

- Axis 4: +-350º

- Axis 5: +-125º

- Axis 6: +-350

Applications

Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts , Laser welding Nd-Yag , Glueing - Adhesive bonding , Plasma cutting

Pictures

Videos

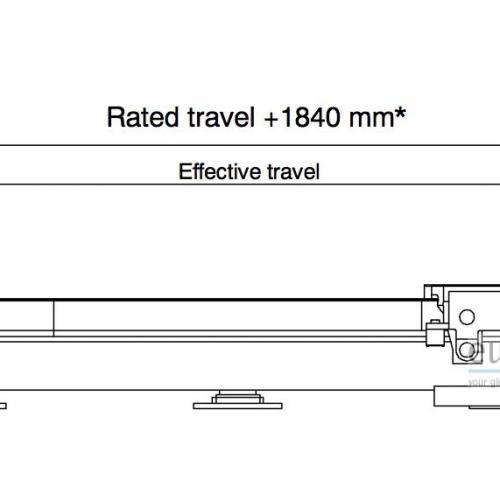

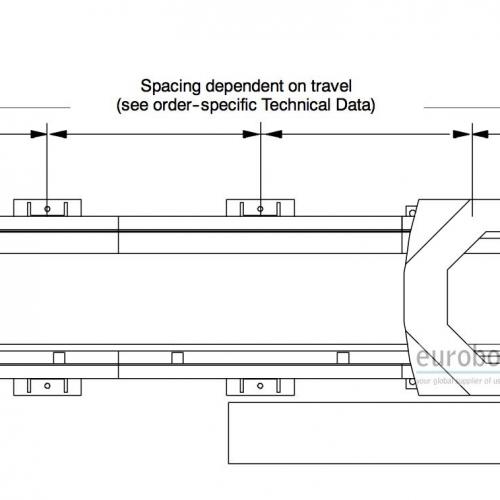

Diagrams