Year 1999. Highest payload version of the famous and reliable S-420iF. The Fanuc S-900H is a six axis robot which features a reduced payload and larger work envelope, suitable for handling applications. Equipped with the RJ2 controller, 16 digital inputs / outputs

FANUC Robotics' S-420i line of robots is engineered for maximum performance and reliability in the automotive body shop and is supported by our extensive application technology and service / parts network. The S-420i features a unique integrated controller, six-axis modular construction and a flexible, electric servo-driven design for high-speed and heavy processes.

Benefits

* Work Envelope allows processing of large fabrications

* Modular robot design allows conversion form one model to another

* Combined mechanical unit and robot controller reduces floor space, point-to-point wiring and installation costs

* Minimal mechanical / electrical parts increase reliability

* High motion speeds reduce time between welds

* Rotation of 360 degree for axis 1

* User power / signal / air lines internal to arm for increased reliability

* Easy-to-learn and use application programming packages

* "QUick change" electronics cabinet reduces downtime to less than 15 minutes

* Low mass arm design allows high-speed positioning

* Proven arm design in over 13,000 S-420 robot installations.

Flexibility features

* Extension arm, heavy payload wrist, wedge pedestal, reduction ratio and balancer modules allow simple robot conversion to single point weld, rack mount, long arm or heavy duty types

* Flexible and expandable I/O system internal to controller

* Distributed I/O blocks to reduce wiring

Mechanical Features

* Mechanical construction provides precise positioning and high motion speed

* Direct drive on all axis results in higher reliability and reduced maintenance

* RV speed reducers provide smooth motion at all speeds and a long life

* Simple modular design with few components

* Sealed bearings and drives provide protection and improve reliability

* Absolute serial encoder positioning

* Wrist axis torque and inertia allows rated motion speed with large guns / tools

* Unique hollow RV speed reducers simplify cable routing

* Compact remote mount operator panel reduces aisle and floor space requirements

* Waist mounted forklift brackets can be used for peripheral and weld transformer mounting

* Compact arm option for close spacing of units

Robot Info

- Maximum Load of Robot: 200 Kg

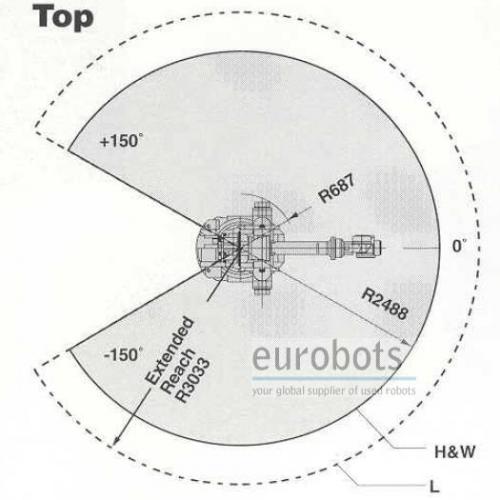

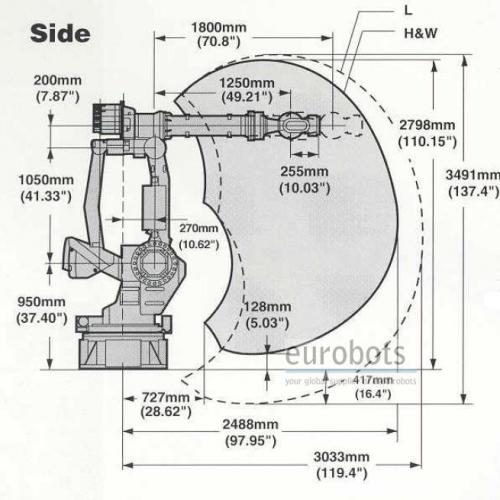

- Maximum Reach: 2488 mm

- Repeatability: 0,5 mm

- Controller: RJ2

Robot Motion Speed

- Axe 1: 90º/s

- Axe 2: 95º/s

- Axe 3: 95º/s

- Axe 4: 115º/s

- Axe 5: 115º/s

- Axe 6: 200º/s

Applications

Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts , Laser welding Nd-Yag , Glueing - Adhesive bonding , Stud welding , Plasma cutting

Pictures

Diagrams