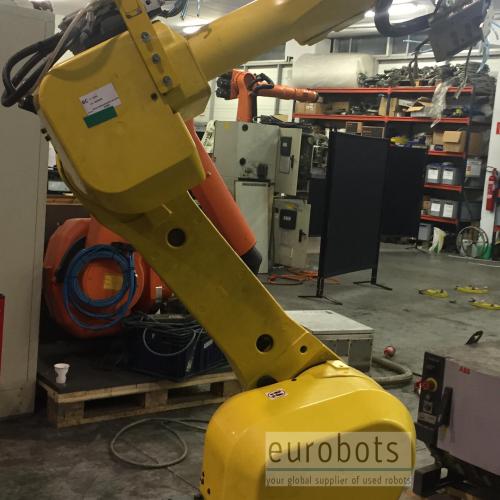

Low payload, 20kg, 6 axis industrial robot. Typically used for handling, extraction of parts from injection machines, machining, etc...

The powerful and user friendly R-30iA control system makes this robot one of the most popular ones in its range.

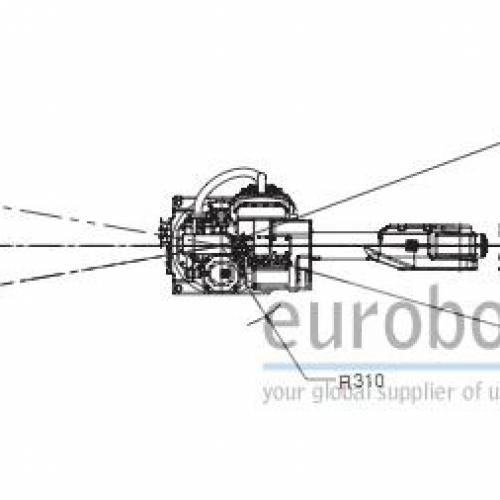

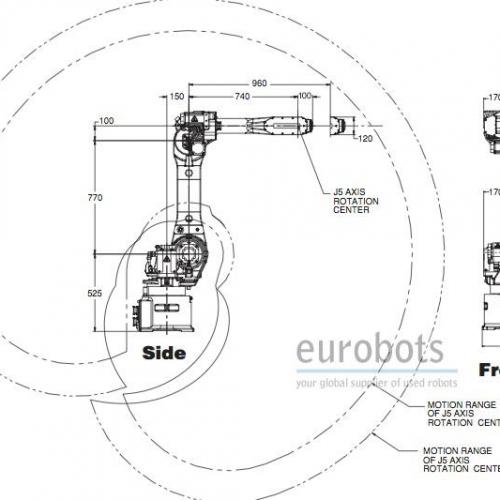

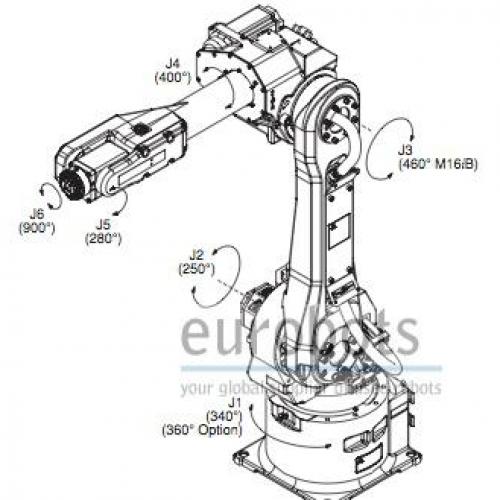

The FANUC M-16iB is a six-axis, modular construction, electric servo-driven robot designed for a variety of industrial applications. Based on its simple and reliable construction, the FANUC M16i provides sophisticated motion control and consistent performance with high productivity.

The FANUC M-16iB features:

• Small footprint supports placement in confined areas

• Dust and water resistant design maximizes durability

• Work envelope and position flexibility are eliminated by absolute serial encoders

• Absolute serial encoders dismiss the need for calibration at power-up

• No modification of robot for upright, inverted, angle and wall mounting

• Best axes speeds in its class

R-30iA features

The R-30iA controller needs less than 1 minute to start (and even less with the basic software only). In case of power failure:

Robot program restarts much quicker than with any PC-based program (non-Windows operating system).

The resume hotstart function allows restarting safely and continuing production after power failure: no need to re-do the whole movement.

Unique resume tolerance check: in case of any program interruption, the robot automatically memorises its position before failure. When the program continues, it checks whether the robot has been moved outside of a preset tolerance. This avoids unexpected movements and collisions.

Increased up-time (robot availability)

VIBRATION CONTROL

Thanks to enhanced hardware and software capacities, the R-30iA controller offers much better robot vibration control. This greatly reduces the robot’s acceleration and deceleration times, leading to reduced cycle times.

WIDE RANGE OF CONNECTIONS (USB2), PCMCIA INTERFACE...

The R-30iA controller has an USB interface in the front panel and a PCMCIA interface inside of the control cabinet featuring additionally:

- 2 serial interface connections (RS232C, RS422) available

- Printer Connect

- Data Transfer (option)

- Sensor interface (option)

- CRT keyboard (option)

- User specific data transfer using KAREL option

This allows fast and economical back-ups and restore of data and programs.

The FANUC iPendant is an intelligent teach pendant and is available as standard (except for PaintTool). Touch screen is available as option.

- Access via Ethernet to web sites

- Pendant view status of peripheral equipment and other robots‘ html web server pages (when available)

- Coloured, multi-windows display

- Customizable screen

- Easier work with the robot, enhanced productivity.