This Robot COMAU Smart5 NM Arc is a 6 axis robot for arc welding with a special design; It is equipped with the powerful C5G controller. It is a robot with a medium load on the wrist, 16 kg, and has an extension: 3100mm. This robot offers superior quality performance and improved versatility thanks to the integrated Hollow Wrist technology. This technology allows the welding torch connection cables to be housed inside the wrist and the energy consumption is reduced to a minimum to ensure eco-compatibility, greatly increasing its performance.

The robot is integrated with the famous Fronius TPS4000 welding machine with 400 amperes of nominal power.

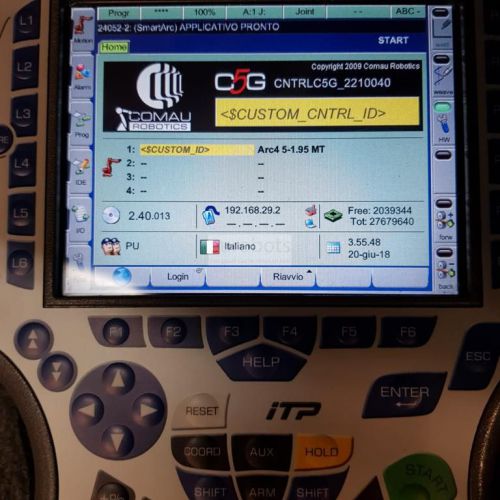

C5G Controller.

The C5G control uses the latest generation of industrial PC APC820 with Core2 Duo CPU technology, able to achieve high performance with low power consumption

Energy saving

• Minimum consumption in standby, low consumption during operations

• Cooling system proportional to the operations of the plant

• Energy network recovers system with a program with a high dynamic content

Flexibility and reliability

The new generation of eld buses based on Hilscher technology, integrated by B & R into their remote X20 I / O family, ensures a reliable and reliable interface in every customer application. Modular interfaces are available such as digital I / O, analog I / Os and for many types of encoder, position transducer, resolver, etc.

Safety

Integrated in the SDM module, TUV certificate (dual-channel emergency stop, enabling device, logic drive enable), braking function on the robot arm and interlock function for human-robot cooperation

Modularity/expandability

Modular system for drives up to 13 axes in the basic cabinet function and the robot model

Simultaneous management of different robots

Hardware architecture designed to manage up to 16 axes in "multi-arm" con guration with application box

Offline 3D programming with Robosim Pro

Management of multiple applications

Ability to manage many applications simultaneously

C5G open controller: become the real engines of the movement of the robot

It allows the development of customized movement algorithms and special applications with the use of sensors

Main features of the software available

- Automatic identification of the payload: automatic identification of the payload to optimize the movement of the robot

- Collision detection: emergency stop of the robot in the event of a collision to protect the mechanic and the equipment

- Cooperative and synchronized movement: coordinated and simultaneous management of various robots and auxiliary axes (linear track, servo-gun, positioners and other application equipment)

- Conveyor and Sensor Tracking: tracking of moving parts on linear and circular conveyors. Accuracy in following the path using different types of external sensors

- Joint Soft Servo Technology: the ability of the individual joints of the robot to yield to the external forces required by the specific application

- Interference Regions: Regions of various shapes can be dynamically defined to limit the robot's workspace

- Robot Absolute Accurancy: algorithm for the adaptation of the real kinematics to the theoretical model programmed off-line

General technical specifications

- Maximum payload of the robot: 16 kg

- Maximum capacity: 3100 mm

- Repeatability in position: 0.05 mm

- Controller: C5G

Movement speed of the robot in º/s

- Axis 1: 170º/s

- Axis 2: 175º/s

- Axis 3: 185º/s

- Axis 4: 360º/s

- Axis 5: 375º/s

- Axis 6: 550º/s

Movement range (Axis 1 to 6)

- Axis 1: +/-180º

- Axis 2: from+155ºto -60º

- Axis 3: from+110ºto -170º

- Axis 4: +/-185º

- Axis 5: +/-123º

- Axis 6: +/-270º

Applications

Pictures

Videos

Diagrams