The 7600 belongs to the heaviest line of heavy duty industrial robots of ABB. This unit was built in 2010.

The IRB 7600 is ideal for weighty applications, regardless of industry. Typical areas can be handling of heavy fixtures, turning car bodies, lifting engines, handling heavy parts in foundries or forges, loading and unloading of machine cells, alternatively handling large and heavy pallet layers.

This robot comes with the IRC5 M2004 (fifth generation of ABB control system) controller which features:

FlexPendant

The FlexPendant is characterized by its clean, color touch screen-based design and 3D joystick for intuitive interaction. Powerful customized application support enables loading of

RAPID programming language

RAPID programming provides the perfect combination of simplicity, flexibility and power. It is a truly unlimited language with support for structured programs, shop floor language

and advanced features. It also incorporates powerful support for many process applications.

Communication

The IRC5 supports the state-of-the-art field busses for I/O and is a well-behaved node in any plant network. Sensor interfaces, remote disk access and socket messaging are examples of the many powerful networking features.

Motion control

The IRC5 supports the state-of-the-art field busses for I/O and is a well-behaved node in any plant network. Sensor interfaces, remote disk access and socket messaging are examples of the many powerful networking features.

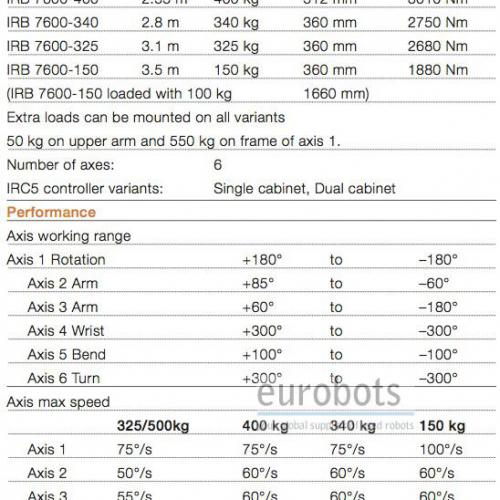

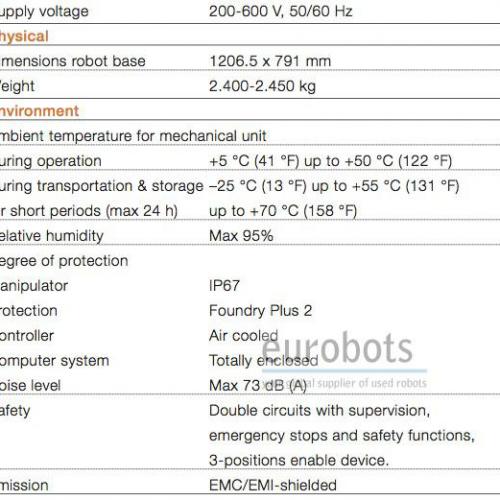

General specifications

- Maximum load of robot: 340 Kg

- Number of axis: 6

- Maximum Reach: 2800 mm

- Repeatability: 0.3 mm

- Controller: IRC5 M2004

Robot motion speed (degrees per second)

- Axis 1: 75°/s

- Axis 2: 50°/s

- Axis 3: 55°/s

- Axis 4: 100°/s

- Axis 5: 100°/s

- Axis 6: 160°/s

Robot motion range

- Axis 1:±180°

- Axis 2 +85°to -60°

- Axis 3 ±60°to -180°

- Axis 4 ±300°

- Axis 5 ±100°

- Axis 6 ±300°

Applications

Arc welding , Spotwelding , Press tending , Palletising , Loading and unloading of parts , Machining , Handling of parts , Polishing , Measurement , Assembly of parts , Laser welding Nd-Yag , Glueing - Adhesive bonding , Plasma cutting , Advanced Manufacturing

Pictures

Videos

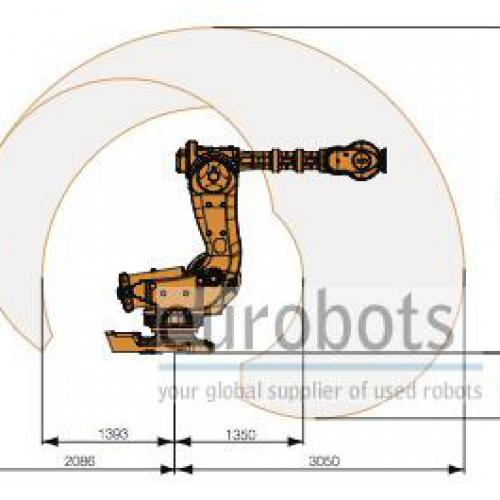

Diagrams