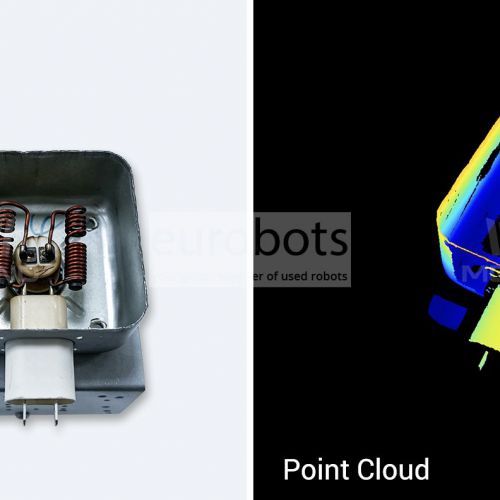

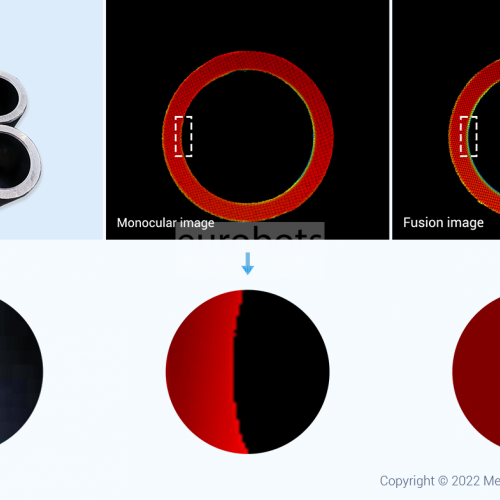

The Mech-Eye UHP-140, when combined with sophisticated image merging and anti-glare 3D rebuilding techniques, is adept at minimizing visual obstructions. This system can produce comprehensive, intricate, and precise point cloud information of intricate and reflective components, even capturing minuscule details effectively.

- The industrial 3D camera Mech-Eye UHP-140, known for its ultra-high precision, excels in producing top-tier point cloud data for subframe features, particularly those with highly reflective surfaces.

- Leveraging an advanced intelligent measurement algorithm, the Mech-Eye UHP-140 adeptly manages a diverse range of feature types such as round holes, threaded holes, studs, etc., ensuring a high level of measurement accuracy.

- Through multi-camera and multi-robot collaboration, it can efficiently address various feature positions and swiftly accomplish measurement tasks for different large parts.

- The resulting measurement data is manageable and organized, offering support for customized history filtering and the generation of comprehensive measurement reports.

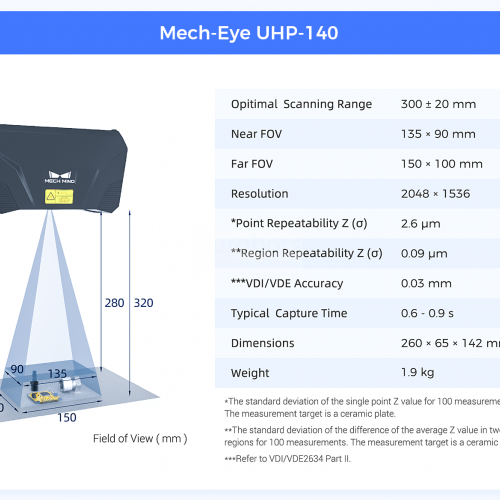

Recommended working distance (mm) : 300 ± 20

Near FOV (mm) : 135 × 90 @ 0.28 m

Far FOV (mm) : 150 × 100 @ 0.32 m

Resolution: 2048 × 1536

Megapixels (MP) : 3.0

Point Z-value repeatability (σ)

[1] : 2.6 μm @ 0.3 m

Regional Z-value repeatability (σ)

[2] : 0.09 μm @ 0.3 m

Measurement accuracy (VDI/VDE)[3] : 0.03 mm @ 0.3 m

Typical capture time (s) : 0.6–0.9

Image sensor: Sony CMOS for high-end machine visionDimensions (mm) : Approx. 260 × 65 × 142

Weight (kg) : Approx. 1.9

Operating temperature (℃) : 0–45

Communication interface: Gigabit Ethernet

Input: 24 V DC, 3.75 A

Safety and EMC: CE/FCC/VCCI/UKCA/KC/ISED/NRTL

IP rating: IP65

Cooling: Passive

Light source: Blue LED (459 nm,RG2)

MTBF (Mean Time Between Failures) : ≥ 40,000 hours

写真

設計図